Precise patterns ensure high accuracy of final product and are one of the most important stages in the manufacturing process of casting items of complex geometry like propellers, rudders and P-Brackets.

CJR uses few different pattern making methods:

- CJR holds stock of hundreds of ready to use propeller, rudder and bracket patterns of our standard products allowing us to offer very fast and cost effective turnaround of standard product.

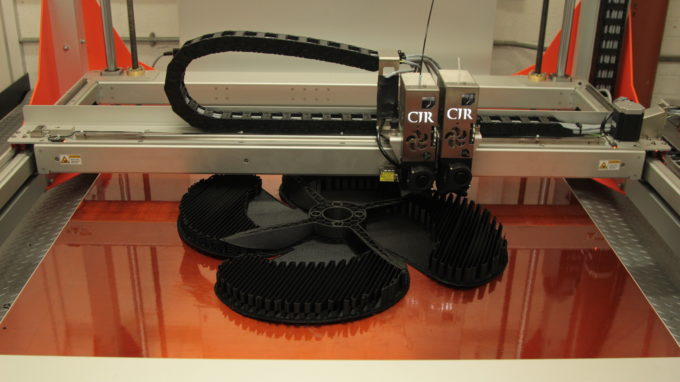

- For newly designed custom propellers, new patterns are printed using one of our in-house state of art 3D printers. We can print any pattern with unmatched accuracy and speed to ours or our customers’ designs, including the ability to reverse engineer product. This method of producing patterns allows for a much more fluid process as the patterns can be printed 24hrs a day, ensuring the fastest possible turnaround of product.

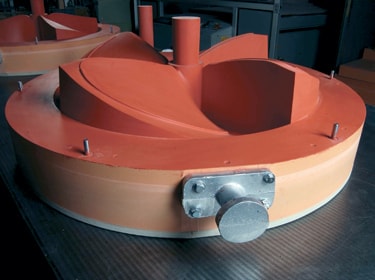

- For production boatbuilders where a pattern will be used hundreds of times, we machine an aluminium pattern using our 5 axis CNC to ensure maximum durability and to ensure bespoke geometry, complicity and accuracy.

Get in Touch

CJR combines decades of experience with continuous investment in the latest technology and engineering prowess. Just drop us a note to find out more about how we can help you.

CONTACT US