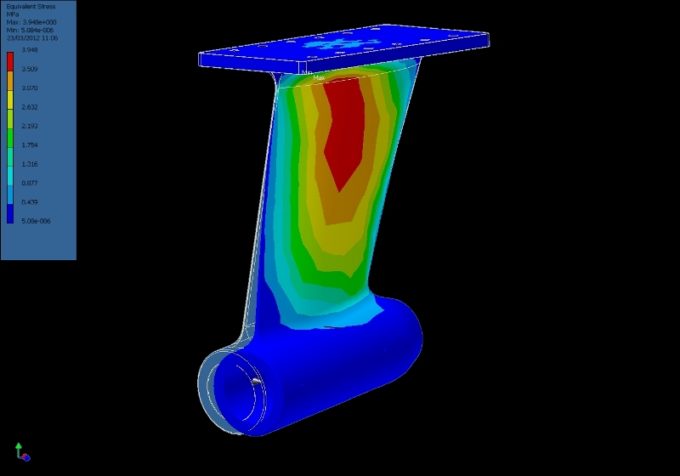

Finite element analysis allows CJR to calculate stresses in complex geometries for given loading conditions.

What is Finite Element Analysis?

A computerised technique called finite element analysis (FEA) can be used to forecast how a product will respond to forces, vibrations, heat, fluid movement, and other physical influences in the real world. Finite element analysis reveals if a product will malfunction, wear out, or function as intended. The product development process uses FEA simulation to forecast what will happen when the component is employed in its real-world application.

FEA Software in Marine Manufacturing

Marine engineers use FEA software to optimise the design for safe, effective, and dependable ships and marine structures. Without having to create physical prototypes or invest in costly trials, they may use it to test and confirm design concepts. Additionally, FEA software can be used to assess and optimise the structural strength, stiffness, fatigue, and durability of ships and marine structures under a variety of loads and environmental conditions, as well as analyse and improve the hydrodynamic performance, stability, manoeuvrability, and resistance of these objects. Finally, FEA software can assist naval architects in adhering to industry and regulatory norms and laws.

FEA Consultancy at CJR

Finite Element Analysis (FEA) is part of CJR’s commitment to precision engineering. It empowers us to delve deep into the intricate complexities of structures and accurately compute stresses under various loading conditions.

At CJR, our team specialises in the expert Finite Element Analysis process. Our professionals use a sophisticated method that, within a predetermined computational domain, converts designs into reliable 3D solid models, especially for our tillers The methodical procedure that comes next is built on this. Boundary conditions are set for the anchor points and external forces are applied.

The thorough visualisations that FEA offers are where its true power is seen. Even the slightest twists in the structure can be precisely observed as deflection patterns. We can identify regions of high-stress thanks to this priceless insight, guaranteeing that every component is durable as well as functional.

These visualisations aid in the development of our designs and provide useful information. Our team starts over when regions of concern appear, showing potential high stresses or an excessive force distribution. We carefully rework the design using our knowledge to make sure it adheres to the highest performance and durability criteria. The consumer may download the created 3D model and import the file into their 3D hull geometry especially for shaft brackets. This ensures that the hull is fitted precisely and accurately before any tooling manufacturing starts.

FEA analysis lowers a vessel’s weight and optimises its structural design while keeping strict safety standards. You will be astounded by the level of depth and clarity of what we produce with the help of our FEA Consultancy. Every aspect of the design can be trusted, and you can have faith that the finished product will be precise and comprehensive.

When areas of concern arise, indicating potential high stresses or undue force distribution, We employ our expertise to meticulously reconfigure the design, ensuring it aligns with the highest standards of performance and durability.

Benefits of FEA

One benefit of using FEA services is the thorough study that goes beyond the scope of urgent structural issues. It gives us the ability to maximise material consumption, leading to designs that are more effective and affordable. We achieve a balance between performance, durability, and resource use by tweaking the geometry and material choice.

The FEA process also plays a crucial role in the initial design phase. Every component is rigorously tested using our FEA simulations before it is put into production. Any areas of concern about high stresses or excessive force are redesigned to meet acceptable criteria. This ensures that our products frequently go above and beyond expectations.

Our 3D finite element analysis design is more closely aligned with the real-world design because of this software. Your digital model’s performance in the actual world can be accurately predicted when forces like heat, mechanical stress, and vibration are applied computationally.

At CJR, we understand that precision engineering is a dynamic field, constantly evolving to meet new challenges and push boundaries. Our commitment to FEA is a testament to our dedication to staying at the forefront of engineering excellence. By integrating cutting-edge technology with decades of expertise, we continue to redefine what’s possible in the world of engineering.

Finite Element Analysis is not just a tool for us; it’s a cornerstone of our commitment to excellence. It enables us to deliver products that don’t just meet specifications but exceed expectations. With FEA, CJR ensures that every component is a testament to the fusion of art and science in engineering.

Get in Touch

CJR combines decades of experience with continuous investment in the latest technology and engineering prowess. Just drop us a note to find out more about how we can help you.

CONTACT US