CJR’s high-performance shafts for sterngear assemblies are manufactured to the most stringent quality standards, typically using Marinemet 25, which is stronger and more resilient to corrosion than even surgical stainless steel and offers the optimal balance of performance and durability. Other materials, including 316L and Super Duplex, can also be specified as required.

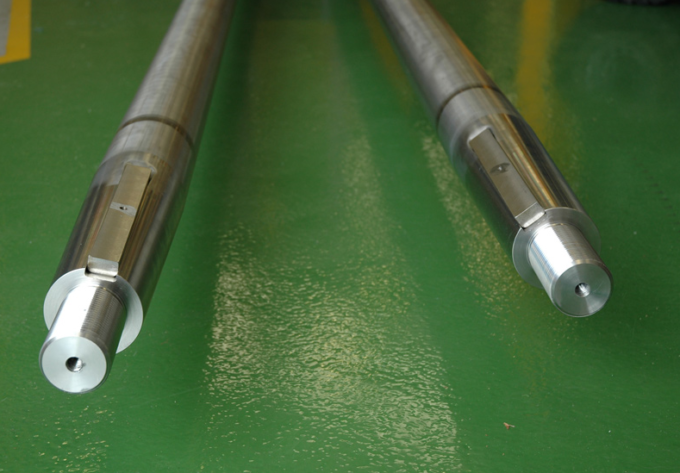

Available from 1.75” to 180mm in diameter and up to 10 metres in overall length, regardless of materials, every shaft CJR produces can be certified against any class society or IACS requirement.

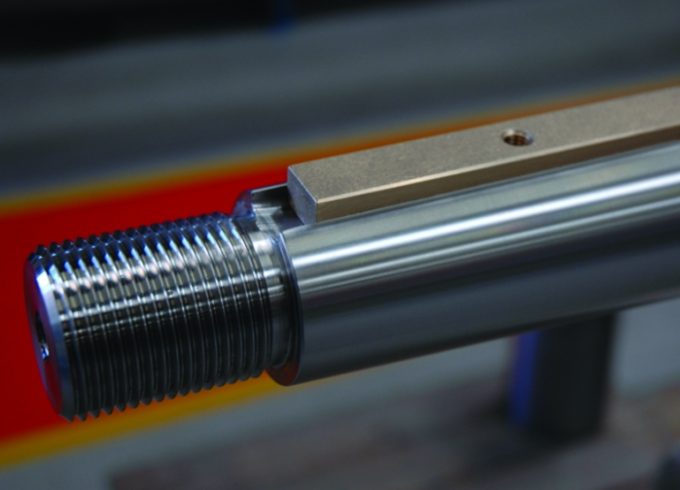

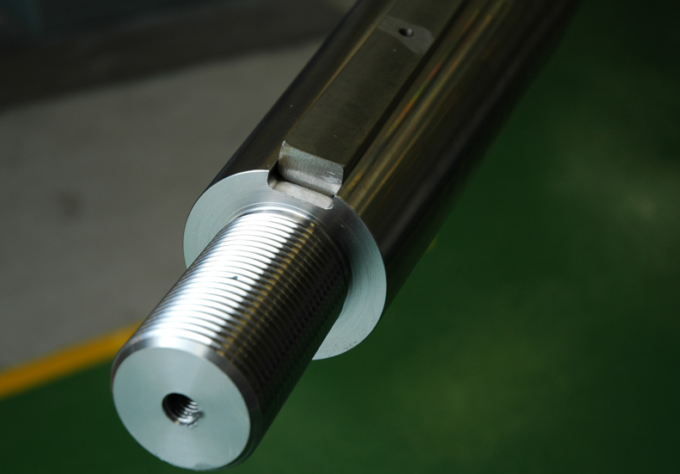

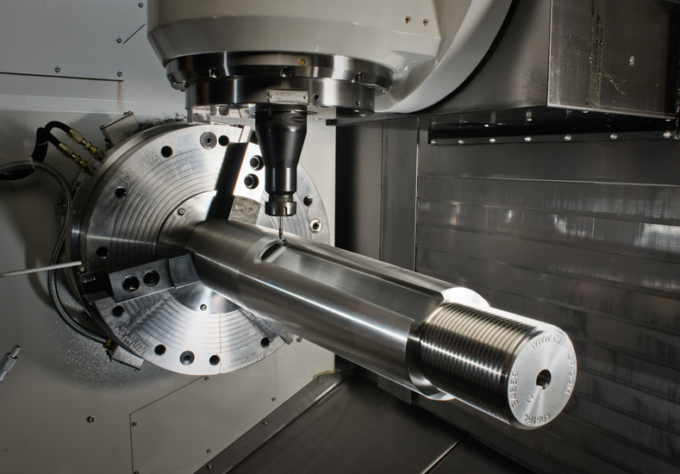

To further simplify the certification process, CJR shafts are fully CNC machined, including keyways, tapers and threads. This ensures a precise fit and accurate adherence to the tight tolerances on straightness and runout on complete shaft assemblies.

Shaft size is carefully calculated using FEA design tools to be safe in operation throughout its lifespan. Every sled keyed shaft is also spooned to avoid stress concentration points in the keyway.

Key information

Shaft diameter: 1.75” to 160mm.

Shaft length: Up to 10m overall length.

Certification: Able to comply with any specific class rules and IACS requirements.

Material options: Marinemet 25, F51 Duplex, 316L, Aquamet 22HS, Aquamet 17 and Super Duplex.

Manufacturing: Fully CNC machined in-house, including keyways, tapers and threads to ensure a precision fit. Manufactured to meet ISO 1:10, SAE 1:16 or BS marine standard 1:12, as well as keyless tapered 1:30. Any other non-standard taper can also be machined on request.

Quality: Adherence to tightest tolerances on straightness and runout on complete shaft assemblies, and checked for accuracy at every stage in the manufacturing process.

Accuracy: Machined in one piece to meet tolerances from 0.005” to 0.02” over a length of up to 9m and 0.005” to 0.01” on taper.

CJR’s dedicated shaft CNC machining centre

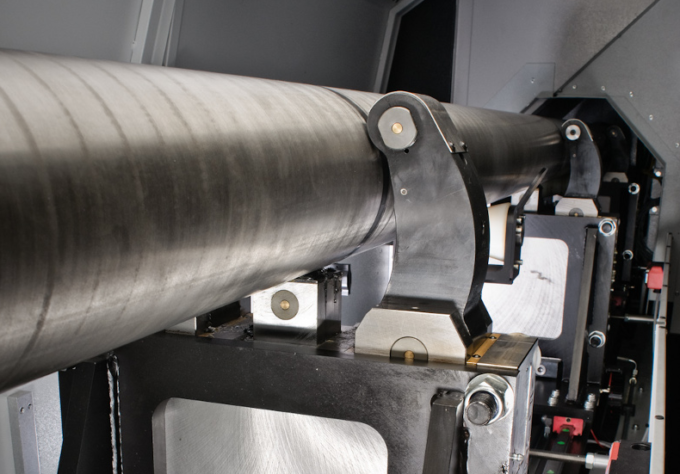

With our own dedicated shaft production centre, we are able to not only provide machining of the shafts themselves but the full assembly and inspection of all CJR shaft-line products; from bar to dispatch.

We precision machine fully ground high strength marine propeller shafts using 5 axis machine tools that allow single set-up manufacturing which greatly reduces inaccuracy, unnecessary handling and the total number of operations.

All shafts leave the works pre-lapped with their respective coupling in order to ensure sound mating taper contact is achieved, which reduces unnecessary fitting time at the vessel.

Installation

CJR offers various services and products to assist with the installation of shafts. These include Shaft Alignment Calculation to assess best bearing positions and offsets, a laser alignment system, a hydraulic coupling pusher/puller for quick and simple keyed coupling and propeller attachment, and Propsmith – a mechanical system for easy propeller fitting and removal.

For keyless hub-shaft connection, CJR can offer a complete hydraulic fitting kit including hydraulic pushing nut and hydraulic pump to expand the hub.

Get in Touch

CJR combines decades of experience with continuous investment in the latest technology and engineering prowess. Just drop us a note to find out more about how we can help you.

CONTACT US