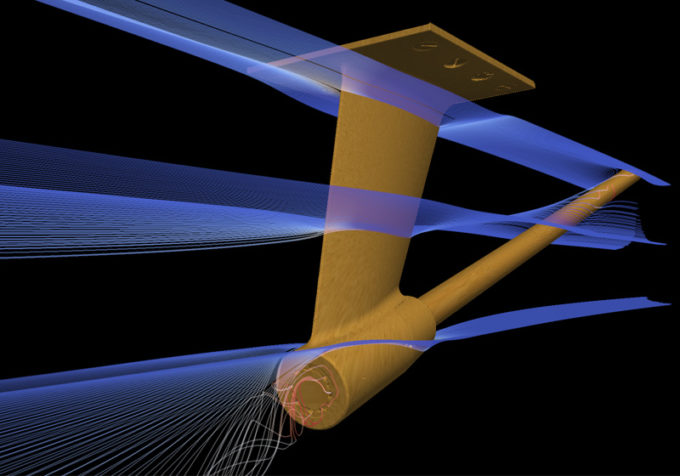

When considered as part of the wider stern gear package, shaft brackets (A and P) can play a significant role in maximising your vessel’s performance efficiency. Fully optimised stern gear setups, including brackets designed using computational fluid dynamics, help to reduce water disturbance and drag. This provides a more comfortable ride, superior performance, improved safety and greater overall longevity due to reduced cavitation.

CJR’s marine shaft brackets range from a bore size of 45mm to 160mm diameter – up to a total weight of 600kg. Every set of brackets is individually crafted, using CFD and FEA design tools to achieve optimum performance and, as a result, offer amongst the lowest total cost of ownership available. This is achieved by taking the time to understand the vessel’s individual requirements and intended application beforehand and collating the data required to deliver a fully optimised solution that meets the customer’s expectations.

With the required data in hand, we build a 3D model for all component drawings to be used for CFD and FEA analysis. The developed 3D model can be issued to the customer, allowing them to import the file into their own 3D hull geometry. This ensures that precise and accurate fitting with the hull is achieved before any tooling manufacture begins.

The CFD difference

Through our computational fluid dynamics (CFD) department, we are able to predict the water flow into the propeller shaft bracket under a myriad of sea states. These complex, fully automated simulations enable us to test and iterate the design and positioning of the bracket and reveal the precise hydrodynamic geometries and strength analysis we need for manufacture.

Once CFD analysis is complete and the design is finalised, the 3D model is then sent to our 3D printers, where we manufacture patterns to be used in the casting process

A low drag aerofoil section is then applied to all struts. This ensures that we deliver exceptional efficiency, peak performance and the lowest vibration levels, every single time.

Manufacturing

Propeller shaft support brackets (A or P bracket/strut) are typically manufactured from high-grade nickel aluminium bronze. They are cast in our own foundry with the latest technology casting processes.

The casting process is controlled to IACS requirements and includes material analysis and NDT testing when needed. Most castings are machined on the latest 5-Axis Machining Centres. Machining in one loading allows CJR to achieve pinpoint accuracy for alignment of palm mounting to shaft bore. All castings are finished to the highest standard and are fitted with water-lubricated bearings which can be IACS approved when required.

Alternatively, all brackets can be fabricated in aluminium, stainless steels, or mild steel as a complete item or component parts.

Installation

Shaft brackets can be bolted into the hull using the palm plate. P struts can be glassed into the hull or alternatively glassed in and bolted through and fittings secured with chock fast. Fitting methods and procedures are to the designer or boat yard’s discretion.

All component parts can be supplied with fixing bolts and backing plates, strips or washers.

Alternatively, all brackets can be fabricated in aluminium, stainless steels, or mild steel as a complete item or component parts.

Each shaft bracket produced under classification society rules is inspected to an IACS approved quality procedure.

Get in Touch

CJR combines decades of experience with continuous investment in the latest technology and engineering prowess. Just drop us a note to find out more about how we can help you.

CONTACT US