Increase your vessel’s performance with a bespoke rudder from the UK’s marine manufacturing experts.

Rudder Efficiency And Hydrodynamics

CJR’s custom, performance-oriented boat rudders have long been a key consideration for discerning boat owners. Our custom-crafted rudders have a notable impact on several factors, including vessel manoeuvrability, responsiveness, fuel consumption and boat speed. In addition, they directly reduce noise, vibration and cavitation levels, making them an imperative component of a fully optimised propulsion package.

Our Boat Rudder Steering Systems

Through the use of CFD and FEA design tools, CJR-designed rudders are tailored to your specific hull form and optimised for peak performance and longevity. Our extensive experience in the marine industry means that we are able to offer our customers the finest boat rudders on the market. This is due to a number of factors:

- Our accurate understanding of the flow into the rudder from the propeller and the hydrodynamic loading.

- Our ability to calculate rudder stock and blade strength requirements.

- Our extensive work around supporting bearings reactions with precision accuracy.

Our rudder design and manufacture can meet any classification society rules, including all IACS societies, and can be cast in a range of materials to suit the specific application. Nickel aluminium bronze (NiBral) is the most popular choices. Equally, CJR’s boat rudders can be manufactured using a range of alternative approaches to best meet your specific requirements.

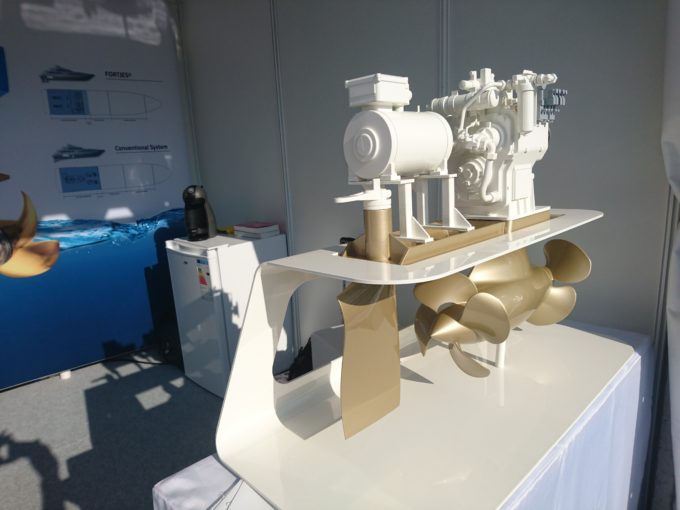

Flow-Aligned Twisted Rudders

In addition to our standard rudders, we also offer our customers the option to invest in pioneering, flow-aligned twisted rudders. Fully tailor-made, our twisted rudders have been specifically crafted to match the rotational flow of water from the propeller. This unique design allows for minimal resistance, increasing boat speed and manoeuvrability, without sacrificing steering.

Read more about flow-aligned rudders here.

Custom Assemblies

Cast Rudders

Cast in a single piece in either aluminium bronze or high tensile bronze, before the stocks are fully machined in our CNC machining centre for adherence to the required tolerances and ensuring optimum fit.

Bolt On Stock

Bolt on stock rudders follow the same quality-centric approach as our cast rudders but with a bolt on stock for easy replacement and repair of the blade if it gets damaged. The stock and blade are fitted with flanges with a ring of bolts which usually fits into a recess in the hull to minimise drag.

Fabricated

Fabricated single plate or streamlined NACA shape rudders are manufactured and welded in stainless steel or mild steel and can offer a notable weight saving for large vessels. All welding is carried out by Class Society coded welders and all our rudder types can be manufactured to major Classification Society requirements.

Common Rudder Issues

Regular maintenance is fundamental to ensure the peak performance and endurance of boat rudders, however over time you may experience issues such as stiff steering, vibrations, leaking bearings and/or reduced manoeuvrability. Below we have underlined some quick troubleshooting you can do to remedy some of these common problems.

For stiff steering: Check for obstructions in the rudder bearings or linkage.

For vibrations: This may signal misaligned rudder blades or bent rudder stocks.

For reduced manoeuvrability: This may result from a damaged rudder blade and you may need to consider replacement.

Boat Rudder FAQs

-

How does a boat rudder work?

A rudder is part of the steering equipment of a boat or ship. It is placed behind the propeller, usually attached to the stern. Its primary use is to change the direction of the vessel through deflecting water flow. When the helmsman turns the tiller or helm, the force increases on one side and decreases on the other, and the rudder will move in the direction of lower pressure. As the rudder turns, so does the stern, and the boat changes direction accordingly. Rudders are operated in different ways depending on the size of the vessel. In larger boats, the rudders are controlled via hydraulic systems, electrical equipment or sometimes steam, whereas in smaller boats, they are manually operated by a handle, called a tiller, or helm.

-

What are boat rudders made of?What are boat rudders made of?

Since inception, boat rudders have been made from a whole host of materials. Before the introduction of high strength stainless steel and aluminium, older ships used crafted wood or bronze to steer their vessels.

At CJR, we offer our customers a variety of materials for custom-made rudders, but we have found the most durable and popular are nickel aluminium bronze (NiBral). This is because this material has a high corrosion resistivity, high mechanical strength and good resistance to shock loading and fatigue.

-

What are the different yacht rudder types?

In modern motor-powered boats, there are three main rudder designs: a balanced, or spade rudder, an unbalanced rudder and a semi-balanced rudder. The key difference between them is based upon the portion of the blade that extends out in front of the stock (the mechanism that turns the rudder). Balanced rudders have around 40% of the rudder area in front of the stock. This set up means a lot less torque is required to rotate it, which in turn lowers the energy requirement of the steering equipment, and the fuel consumption of the ship.

An unbalanced rudder is where the entire rudder blade is positioned behind the stock, which, in opposition to the balanced rudder, requires much more torque to move the steering equipment and rotate the blade. It does, however, provide good structural support. Due to the additional pressure on the steering, this type of rudder is less frequently used in modern boats.

A semi-balanced rudder sits between the two, with 20% of its rudder blade sitting ahead of its stock. This is a popular choice with ship designers for modern vessels, as it relieves torque pressure on the steering gear apparatus, but also aids in structural support to the rudder from vertical displacement.

-

What is used to turn the rudder of a ship?

Typically vessels use hydraulic steering or electric steering systems. This offers smooth and easy control, and as such, is the most common type of power steering on larger or higher horsepower boats. Mechanical steering is another alternative, however only suitable for smaller boats up to 10m in length.

-

When was the boat rudder invented?

Evidence of the first sternpost-mounted rudder goes back as far as Ancient China, depicted on a pottery model of a Chinese junk ship created in the 1st century AD. In Europe, the earliest known representation of a boat rudder appears on a font in a Belgian church (Zedelghem), dated around 1180. Evidence of practical use can be found on medieval sailing ships, where rudders were hung from boats’ stern posts and controlled by tillers.

Get in Touch

CJR combines decades of experience with continuous investment in the latest technology and engineering prowess. Just drop us a note to find out more about how we can help you.

CONTACT US